製品説明:

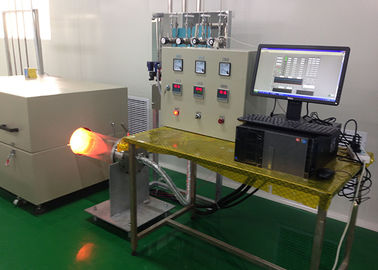

工業用陶器炉は高温炉で 厳格な産業用用途の要求に応えるように 設計されていますこの炉は,制御された加熱環境を必要とする様々なプロセスに最適です頑丈な構造と高度な温度制御機能により産業用陶器炉は,生産における最適な性能と一貫性を保証します現代の製造施設で不可欠なツールです

産業陶器炉の特徴の一つは,通常300mm x 300mm x 300mmの変容容室サイズである.このサイズは,部屋全体に均等な熱分布を維持しながら,異なる寸法のセラミックコンポーネントを処理するための十分なスペースを提供するために慎重に選択されています変形容量の部屋は,さまざまな生産ニーズに対応し,ユーザーは特定のプロジェクト要件に合わせて炉をカスタマイズすることができます.細かい複雑な部品や 大きな陶器部品を扱う場合でもこの炉は,信頼性と効率的な加熱性能を提供します.

温度制御は陶器加工において 非常に重要です精密な仕様を満たすよう細かく調整できる高温能力を提供することでこの点で優れています炉は,陶器材料のシンテリング,火付け,焼却に必要な高温に達する能力があります.最終製品が望ましい物理的および化学的特性を持つことを確保するこの温度管理の精度は,製品の質を向上させ,廃棄物を削減し,全体的な製造効率を向上させます.

産業用使用者の多様なニーズを理解して,産業用陶器炉は固定型と移動型の両方で提供されています.固定型は,生産ラインや実験室内での恒久的な設置のために設計されています.安定して安全な暖房環境を提供します.モバイルオプションは,炉を頻繁に移動したり,複数の場所に使用したりする操作に柔軟性がありますこの汎用性により,異なる産業用シナリオで使用可能性が向上し,高度に適応可能な機器となります.

産業用陶器炉への投資は,長期にわたる品質と耐久性へのコミットメントを表しています.このことをサポートするために,製品は1年から2年の製造者保証付きです.この保証は,買い手に炉の信頼性を保証し,潜在的な製造欠陥や性能問題に対するカバーによって心の安らぎを提供します.製造者の支援は,高品質の炉と顧客満足への取り組みをさらに強調します.

産業用陶器炉の価格は交渉可能で,製品のカスタマイズ可能な性質と異なる産業顧客の異なる要求を反映しています.潜在的購入者は,特別のニーズと需要量の議論を促し,価格設定の選択肢を合わせる.この柔軟性により,小規模な研究室から大規模な製造工場まで,様々な産業や用途に利用可能になります.

総括すると,工業陶器炉は,工業陶器加工の厳しい条件のために設計された,高性能で汎用的な炉です.高温の精密な能力固定型と移動型の両方のオプションにより,どの陶器生産環境でも貴重な資産になります. 1-2年間の製造者保証と交渉可能な価格によってサポートされています.工業陶磁炉は,信頼性の高い効率的でカスタマイズ可能な暖房ソリューションで 現代の産業のニーズを満たしています

応用:

中国産のヤンヤンティアン工業陶器炉は,様々な産業用アプリケーションの要求に応えるように設計されています.固定式と移動式の両方のオプションが利用可能であるため,その多様性は強調されています容積は通常 300mm × 300mm × 300mm で,このコンフィギュレーションは,この工業陶器炉は,陶器製品の幅広い範囲を容認します精密な加工と発火を可能にします

ヤンヤンティアン産業陶器炉の主要な応用機会の1つは,電子機器,自動車部品,航空宇宙産業で使用される先進陶器の製造です.オーブンの異常な温度均一性恒常温度圏内では ± 5 °C の範囲で維持され,陶器部品の品質と性能が一貫していることを保証します.厳格 な 熱 特性 と 構造 完全 性 を 要求 する 部品 を 製造 する 時,この 精度 の レベル は 極めて 重要 です.

製造業に加えて工業陶器炉は,材料科学者とエンジニアが新しい陶器製剤とシンタリングプロセスをテストする研究開発ラボで広く使用されています信頼性の高い温度制御と可変な室の大きさにより,実験設定や小量生産に最適です. さらに,頑丈な設計と 1-2 年間の製造者保証のおかげでオーブンは信頼性の高い動作と長期間の使用を保証し,使用者に安心感を与えます.

耐火材料,タイル,ポルセラン の 生産 に 携わる 産業 も,ヤンヤンティアン 工業 陶器 炉 から 恩恵 を 受け て い ます. The furnace’s electric power specification of not exceeding 60KW at 380V ensures efficient energy consumption while delivering the high temperatures necessary for firing dense and durable ceramic productsこのパワーと効率のバランスは,性能を損なうことなく,継続的な産業使用に適しています.

総じて,ヤンヤンティアン産業陶器炉は,産業製造,研究開発,材料試験を含む幅広い用途のための汎用的で信頼性の高いソリューションです.精密な温度制御柔軟な持ち運びのオプションにより,一貫した高品質の陶器加工を求める専門家にとって不可欠なツールとなっています.

カスタマイズ:

Yanyangtianは,あなたの特定の高温加工ニーズを満たすために設計された パーソナライズされた産業陶器炉ソリューションを提供しています. 中国からリードブランドとして,私たちの産業陶磁炉製品には,先進的なモジュール式組立炉構造があります柔軟で効率的な構成が可能になります.

私たちの産業陶磁炉は,広さ600~1200mmから高さ200~350mmまでの部屋のセクションサイズで調整され,あなたの産業用アプリケーションのための最適なスペース利用を確保することができます.電力仕様は60KW/380Vを超えないため,これらの炉はエネルギー効率を維持しながら信頼性の高いパフォーマンスを提供します.

Yanyangtianは,あなたの運用要件に合わせて,多角的な工業陶磁炉のデザインを提供しています.優れた耐久性と機能性のためにあなたの高温炉をカスタマイズするために私たちの専門知識を信頼.

サポートとサービス

工業用陶磁炉は 要求の高い産業環境で 優れた性能と信頼性を 提供するように設計されています我々は包括的な技術サポートとサービスを提供します.

設置ガイド,運用訓練,トラブルシューティング,および保守手順であなたを助けるために私たちの技術サポートチームは利用可能です.オーブンの特徴と仕様を徹底的に理解するために詳細なマニュアルとドキュメントを提供しています.

効率を維持し,予期せぬ停止時間を防ぐために定期的な保守サービスが推奨されています. 私たちのサービスパッケージには,検査,校正,部品交換,ソフトウェアのアップデート.

技術的な問題があれば 専門家は迅速に 診断し 問題を解決し 生産プロセスに 障害を最小限に抑えることができますまた,変化する産業要件を満たすためにカスタマイズされたソリューションとアップグレードを提供しています.

ユーザー体験を向上させるため スタッフに安全で効率的に 炉を操作し 維持するための知識を与えることを目的とした 研修会やワークショップを 提供しています

専門的なサポートとサービスチームを信頼して 産業用陶器炉を最高性能で動かし 質の高い成果を保証し 投資を最大化します

梱包と輸送:

輸送中の最大限の保護を保証するために 慎重に包装されています各 ユニット は 高 質 の 緩衝 材料 で しっかり 包み,衝撃 や 振動 に よっ て 損傷 を 防ぐ ため,頑丈 な 木製 の 箱 の 中 に 置か れ ます.

梱包物は,厳しい運輸条件に耐えられるように設計され,安全な卸荷と設置を容易にするための明確な取り扱説明が含まれています.

輸送については 信頼性の高い物流パートナーと連携して 炉を迅速かつ安全に 施設まで届けます配送プロセス全体でご連絡を頂くため,追跡情報は提供されます..

税関書類と国際輸送規制の遵守は 経験豊富なチームによって処理され 順調で間に合う清算を保証します

FAQ:

Q1: ヤンヤンティアン工業陶磁炉はどの用途に適していますか?

A1: ヤンヤンティアン工業陶器炉は,陶器製造,金属工学,材料科学産業における高温シンター,焼却,熱処理プロセスに最適です.

Q2:ヤンヤンティアン工業陶器炉はどこで製造されていますか?

A2: ヤンヤンティアンの工業陶器炉は中国で製造されており,高品質の生産基準と信頼性の高い性能を保証しています.

Q3: ヤンヤンティアン工業陶器炉の最大稼働温度は?

A3: 炉は1600°Cまで温度に達し,幅広い産業用陶器加工用品に適しています.

Q4: ヤンヤンティアン工業陶器炉はどんな制御システムを使っているの?

A4: 高度なデジタルプログラム可能なコントローラが搭載され,正確な温度制御とプログラム可能な加熱サイクルを可能にし,一貫して効率的に動作します.

Q5:ヤンヤンティアン工業陶器炉のエネルギー効率は?

A5: 炉は高品質の保温材料で設計され,熱損失を最小限に抑え,エネルギー効率を向上させ,運用コストを削減します.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!